Overview

Ceramic is known for its extraordinary mechanical and electrical properties; it is tough, durable, inert and resistant to chemicals, abrasion and high temperature. These characteristics make it very well suited to use in high-tech industries and for exclusive consumer goods.

Specialized in manufacturing technical ceramic parts we enable production from small to large batch size series. We offer co-development with the customer to optimize the design of their technical ceramic parts to produce it in the best way possible. With five different ways for production and optional assembly in four different types of ceramic we enable manufacturing upon specific customer request providing the right material properties suited best to your application.

Alumina (Al2O3)

One of the most commonly used ceramics in high-tech applications is Alumina (Al2O3) because of its wear resistance and its high chemical and temperature stability. Applications for Alumina can be found in water purification, insulators, semiconductor components, and medical implants. Also, the electric properties are a unique selling point of Alumina.

Properties

low electric conductivity, high resistance to thermal shock, abrasion and chemical attack, high strength, extreme hardness and high melting point (~2,050 °C, or 3,700 °F). It is nontoxic and will not soften, swell or disintegrate in water and has good thermal conductivity.

Example applications

spark-plug insulators, wire guides mechanical parts and sensor housings.

Alumina is used in automotive, mechanical engineering, oil, chemical and petrochemical industries.

Zirconia (ZrO2)

Zirconia has an outstanding resistance to wear thanks to its exceptional strength and high toughness. It is also very resistant to corrosion, therefore it is often used as replacement of conventional metal alloys.

Properties

biocompatible, chemical inertness, high fracture resistance and flexural strength, low thermal conductivity.

Example applications

crowns and bridges, bearings, gears and jewelry.

Zirconia is particularly known for its use in dentistry, but is also a great material to choose for joining ceramic and steel as it has a very high thermal expansion.

Alumina Toughened Zirconia

Alumina Toughened Zirconia (ATZ) is a composite material. The toughness of alumina can be improved by the addition of zirconia particles offering several advantages as it allows the coupling of the good properties of both alumina as zirconia.

Properties

high hardness and strength, chemically inert, biocompatible, high thermal conductivity and electrically insulating.

Example applications

orthopedic prosthetics, industrial cutting tools, nozzles, thread guides, fluid management and dental implants.

ATZ finds it application in diverse industries; oil & gas, biomedical, dental and mechanical and plant engineering.

Electrostatic Discharge material

Electrostatic Discharge material (ESD) is safe to use for products that are sensitive to electrostatic breakdown. ESD is a ceramic mixture containing semi-insulative zirconia for ESD dissipation.

The mixture’s material properties

It is safe to use for products that are sensitive to electrostatic breakdown. ESD is a ceramic mixture containing zirconia and a conductive element for ESD dissipation.

Example applications

Pick-and place tools, tweezer tips and insulators.

ESD-safe ceramics mainly find application in the electronics industry.

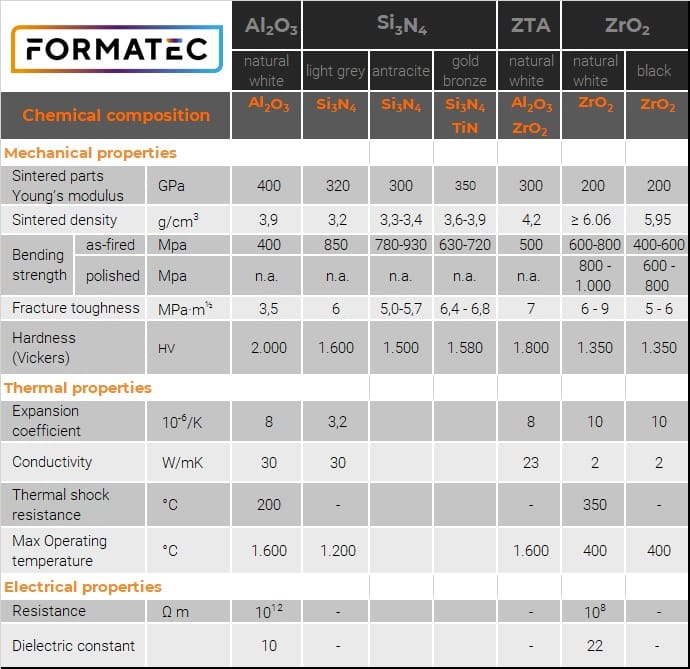

Ceramic material properties

The table below shows the properties of the different types of ceramic we can offer;