Overview

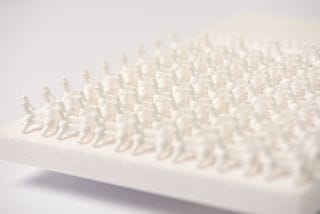

Technical ceramics are used for those critical applications in the medical, high-tech, automotive and other industries where conventional materials like metals or high performance plastics do not perform. But often during the product development phase of such high performance materials the production of prototypes and small initial series is time consuming, difficult and expensive. Formatec is the first company in the world offering both the 3D printing technology and the machine capacity for product development support and serial production to these demanding industries.

At Formatec, we apply the Admaflex Technology which originates from Stereolithography (SLA) but in an updated version called DLP (Digital Light Processing). This specific way of Additive Manufacturing is currently the most reliable and precise additive technique available. It uses photosensitive liquid polymers, mixed with either ceramic or metal powder, cured through light. AM through DLP enables producing high quality products for demanding markets.

THE BENEFITS

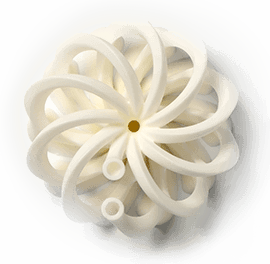

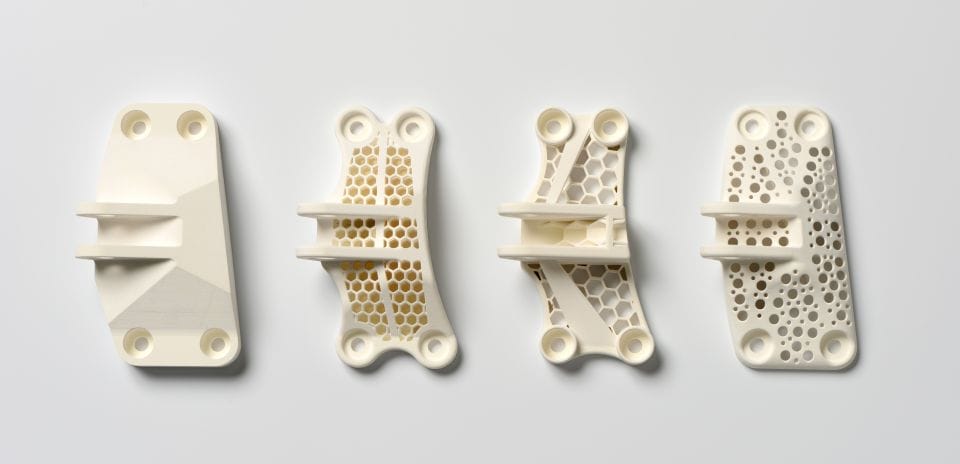

- Free forming capabilities allowing complex shapes

- Alternative to high perfromance plastics: low weight, corrosion, wear and hight temperature resistance

- Complex geometries with tight dimensional tolerances and smooth surface

- Reduced Time to Market, compared to Injection Moulding

- Specifically beneficial for one piece to small series production

- Low batch start-up cost and time

- Low material waste

APPLICATIONS

When integrated designs and functional material structures are required to improve performance, the benefits of Additive Manufacturing are evident. Additive Manufacturing provides benefits for time saving, waste minimization and cost reduction. AM finds applications in automotive, biomedical, electronics, aerospace, energy, chemical and jewelry.

Additive manufacturing materials

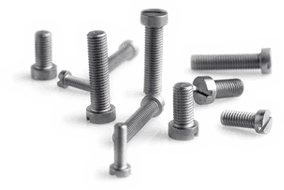

We can offer Additive Manufactured products in both metal as ceramic. Our portfolio includes:

- Ceramics: Alumina, Zirconia, Silica, Hydroxyapatite

- Metals: 316L, 17-4 PH, Inconel 625, Copper

Additionally we have the ability to develop custom metal or ceramic slurry for Additive Manufacturing together with our partner Admatec Europe.

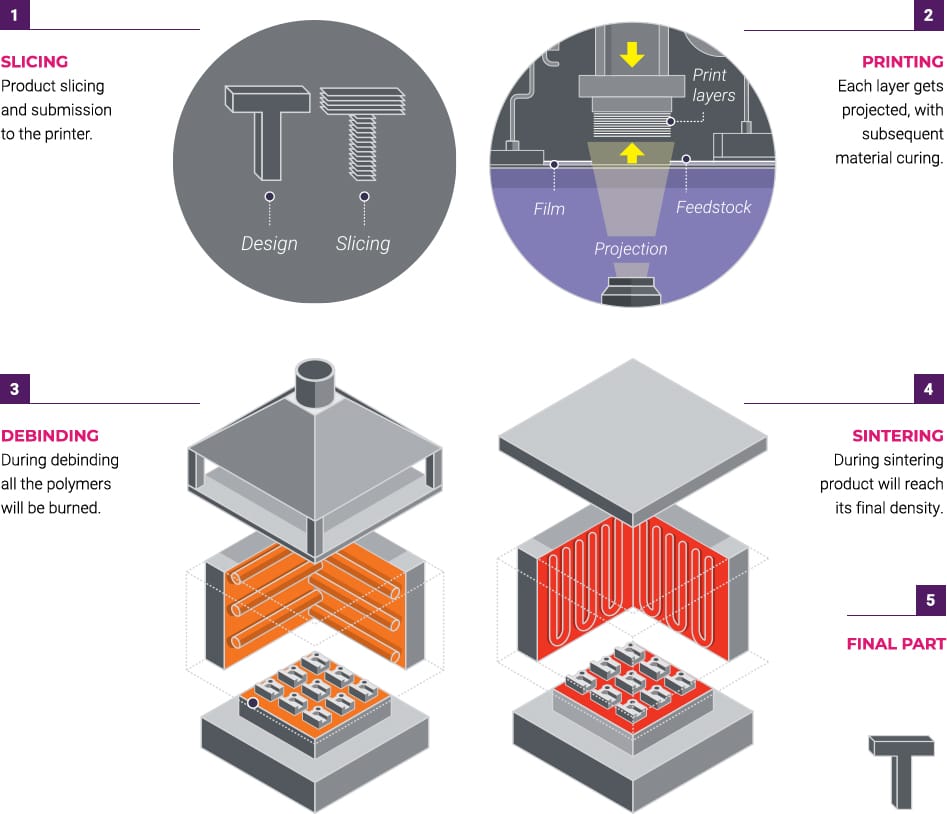

Process

From design to manufacturing of functional parts with form freedom

If you are looking for ceramic and/or metal parts with high accuracy, surface quality and durability for high demanding applications in small batches, Additive Manufacturing is a very interesting option for you!